our product

Infiniguard® outperforms traditional coatings with its ultra-durable, siloxane-based formula that bonds at the molecular level, delivering unmatched corrosion resistance, efficiency gains, and long-term protection. Proven in the harshest conditions, it’s the industry-leading solution for extending HVAC life and performance.

features

Infiniguard® coats every critical component — including coils, cabinets, tubing, and electrical panels — forming a seamless barrier against corrosion, moisture, and contaminants. No surface is left exposed.

Full system protection

boosts hvac efficiency

By reducing friction and improving laminar airflow across coils, Infiniguard® increases system efficiency by 8–13%. Units run smoother, use less energy, and experience less wear over time.

extreme durability

With a dry film thickness of just 0.5 mils, this thin yet powerful coating resists salt, UV rays, abrasion, and chemical exposure. It’s built to last in even the harshest coastal and high-humidity environments.

stops odor at the source

Infiniguard® uses a siloxane-based, inorganic coating that chemically bonds to metal at the molecular level. Unlike traditional organic coatings, it won’t peel, crack, or degrade — providing long-lasting, non-porous protection that stands up to salt, moisture, and extreme environments.

siloxane based formula

Infiniguard® uses a siloxane-based, inorganic coating that chemically bonds to metal at the molecular level. Unlike traditional organic coatings, it won’t peel, crack, or degrade.

fda certified

Once cured, Infiniguard® is FDA-certified for food preparation surfaces, making it safe for use in sensitive areas. It can be applied to both new and existing units — even directly in the field.

test scores

At Coastline Coating, we promise fast, reliable service without cutting corners. From deep cleaning to full-coverage spraying, we treat every unit like it’s our own — delivering results you can count on.

salt spray test

12,000 Hours+ (ASTM B117)

humidity test

2,000+ Hours (ASTM D2247)

UV test

2,000+ Hours (ASTM G154)

cyclic corrosion test

120+ Cycles (SA J2334)

pencil hardness

6H (ASTM D3363)

mandrel bend test

Passed 1/8” (ASTM D522)

fungal growth test

No Growth (ASTM D522)

cross hatch adhesion

5B (ASTM D3359)

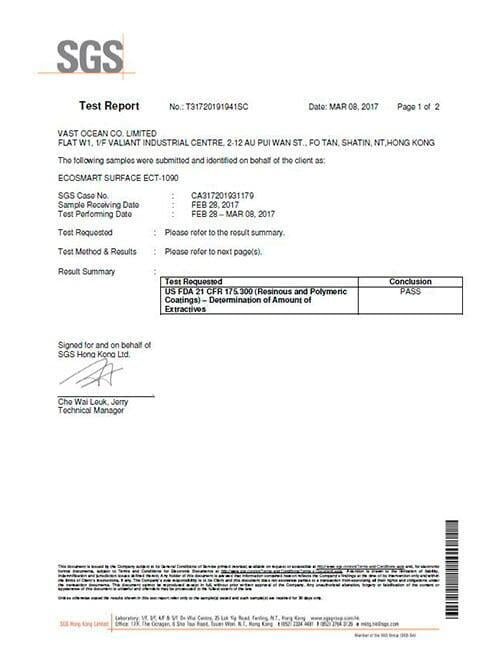

official documents

technical data

third party testing

Trusted Across The Carolina Coast

Ready to Protect Your HVAC Units?

Wilmington Location

Location

3128 Kitty Hawk Rd. Wilmington, NC 28451

Hours

Monday–Friday

8am–5pm

Phone

(910) 622-0013

Myrtle Beach Location

Location

1531 Absco Dr. Longs, SC 29568

Hours

Monday–Friday

8am–5pm

Phone

(571) 288-7392