Coastline Coating

Precision Coating. Proven Protection.

At Coastline Coating, we stop corrosion before it starts. Our full-unit protective coatings keep your equipment performing like new, even in the harshest environments. With fully traceable protection, 24-hour turnaround, and a minimum 5-year corrosion-free guarantee, we remove the risk so you can focus on running your business.

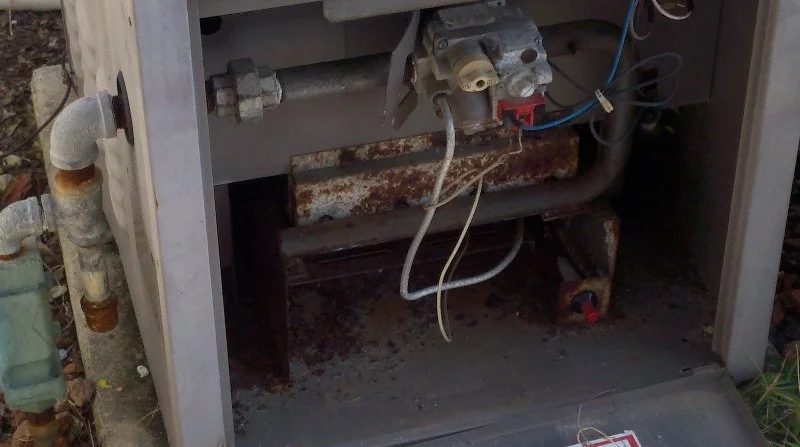

Coastal corrosion

Nags Head

Wilmington

Coastline coated!

Nags Head

Wilmington

Coastal corrosion

Nags Head

Myrtle Beach

Wilmington

Emerald Isle

Coastline coated!

Nags Head

Myrtle Beach

Wilmington

Emerald Isle

Why contractors use coastline coating

We take All corrosion risk for 5+ years

Every coated unit is backed by a minimum 5-year warranty, giving contractors confidence that corrosion protection is handled and long-term risk is off their plate.

true full unit coverage

While most coatings only protect the coil and compressor, our process coats the entire unit; coils, compressor, cabinets, fasteners, even electrical panels, ensuring consistent protection where corrosion actually starts.

24 hour turnaround Guarantee

Fast, reliable turnaround keeps equipment moving through the supply chain even during peak season. Trust us to handle large orders that would otherwise delay jobs by weeks.

Tracked, documented, accountable

Each unit is logged and QR-tracked, providing clear documentation, traceability, and confidence from coating through installation. This information is accessible to all clients via scanning the QR code on every unit.

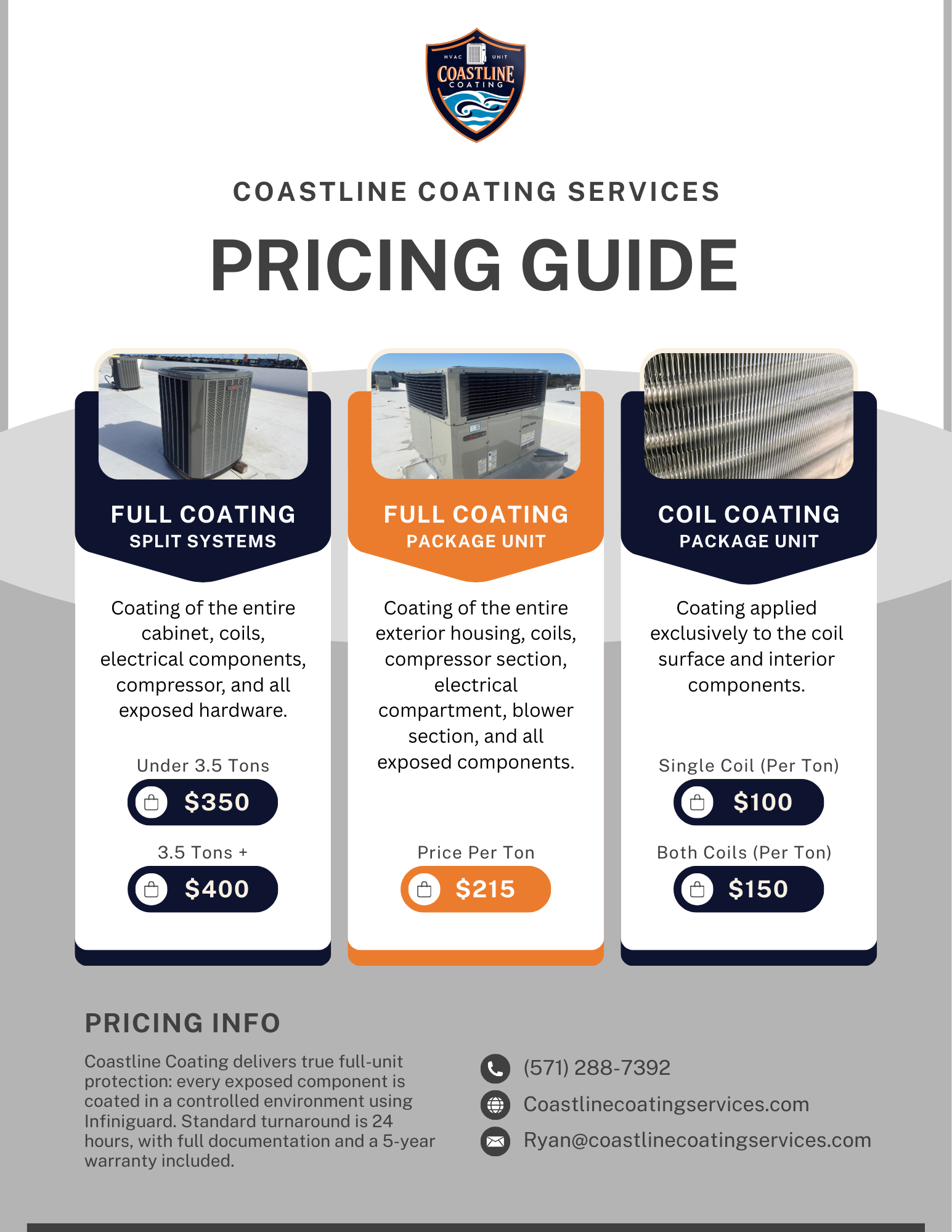

Lowest pricing guarantee

We deliver premium, full-unit corrosion protection at a predictable, lowest flat rate, that helps contractors protect margins while offering the best product to their customers.

Door front delivery service

We deliver coated, job-ready units directly to your shop or the jobsite, wherever you need them, so your team stays focused on installs, not logistics.

Company information

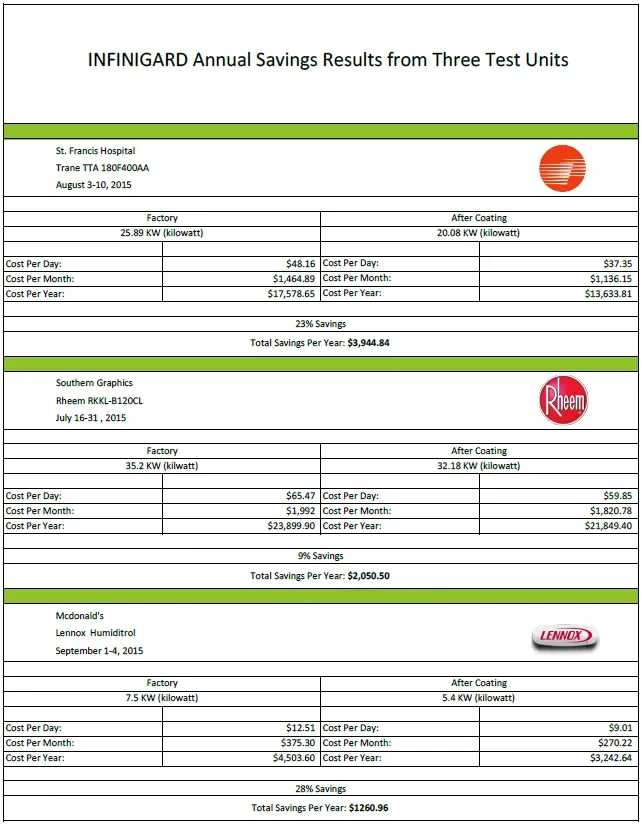

Product information

your Unit saved!

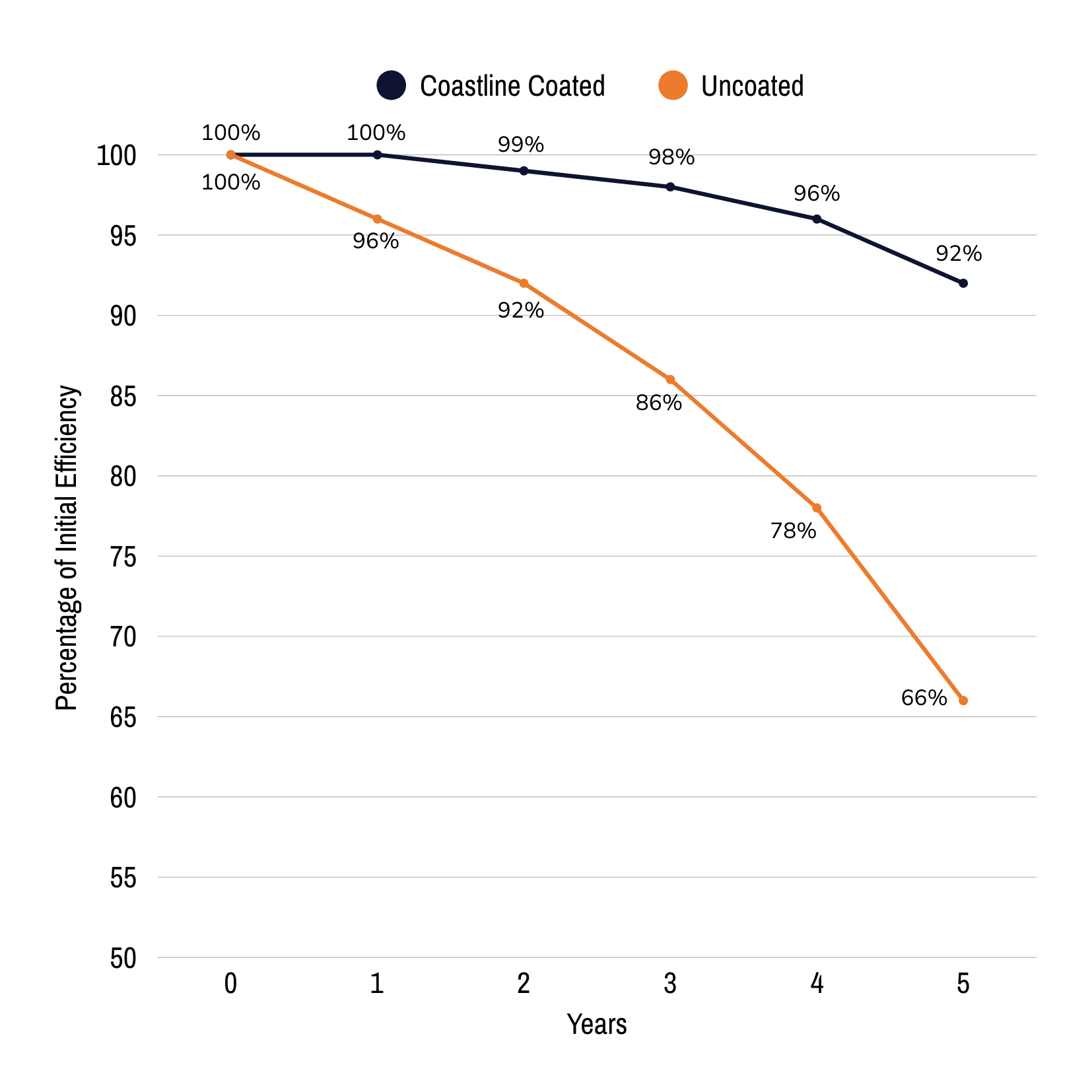

average degredation Analysis

*Energy Efficiency Rating (EER) Effects of Accelerated Salt Spray “Life” Testing of Identical coated and Uncoated HVAC Units.

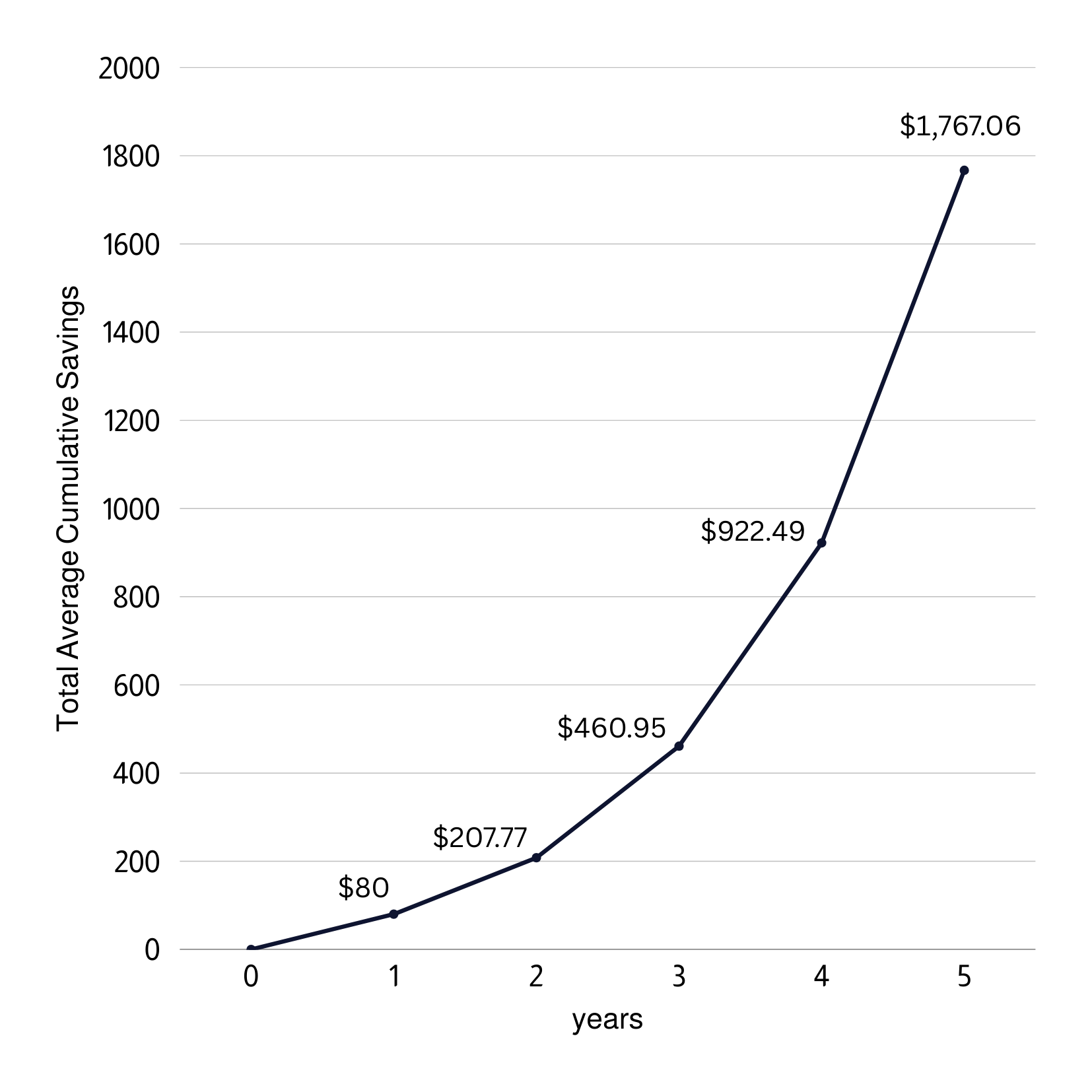

your money saved!

average energy bill savings

*Total average cost savings results of HVAC Unit correlated to Energy Efficiency Rating difference.

Trusted Across The Carolina Coast

company information

product information

our coastal partners

Get Coated!

Come visit!

Wilmington Location

Location

3128 Kitty Hawk Rd. Wilmington, NC 28451

Hours

Monday–Friday

8am–5pm

Phone

(910) 622-0013

Myrtle Beach Location

Location

1531 Absco Dr. Longs, SC 29568

Hours

Monday–Friday

8am–5pm

Phone

(571) 288-7392

Get Coated!

Come visit!

Wilmington Location

Location

3128 Kitty Hawk Rd. Wilmington, NC 28451

Hours

Monday–Friday

8am–5pm

Phone

(910) 622-0013

Myrtle Beach Location

Location

1531 Absco Dr. Longs, SC 29568

Hours

Monday–Friday

8am–5pm

Phone

(571) 288-7392